Let us understand SAP’s product costing & how to get costs breakup in production order for Make to Order scenario

SAP product costing by order process:

For any manufacturing organization, it is utmost important to control the costs of manufacturing. In SAP product costing by order, we calculate the planned cost before production and then during production, we book the actual costs of raw material, machines, labor and overhead costs.

Once the production is over, we must settle the production cost against material master, sales order or WBS element. For more details please follow SAP’s documentation on product costing. An analysis of planned vs actual cost will give you an overview that something went wrong either in planning or in production.

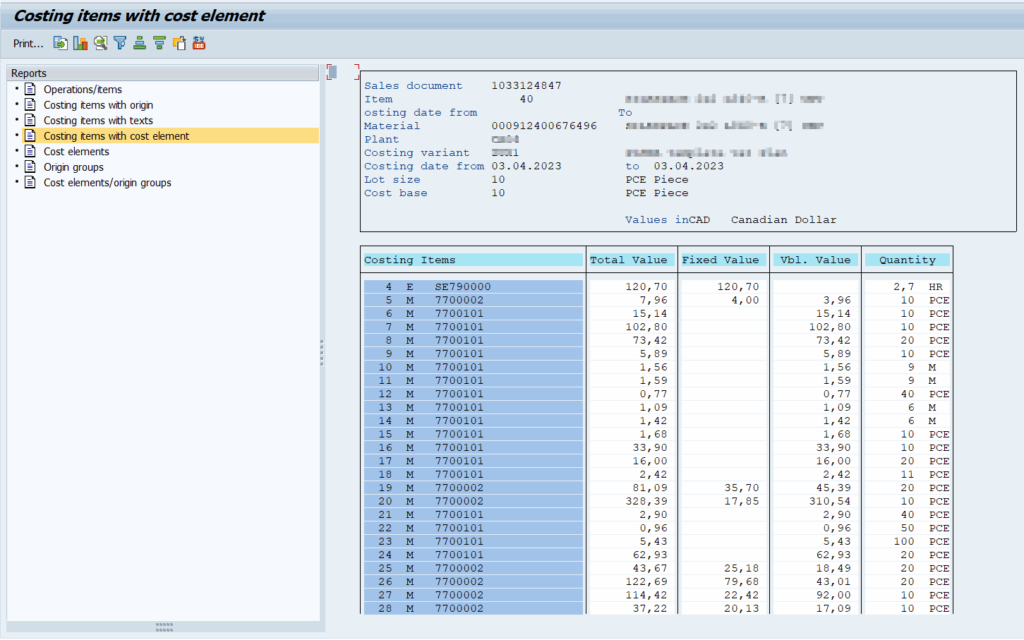

In SAP you can see these costs in production order by following menu: Goto – Costs – Itemization

How to get costs breakup:

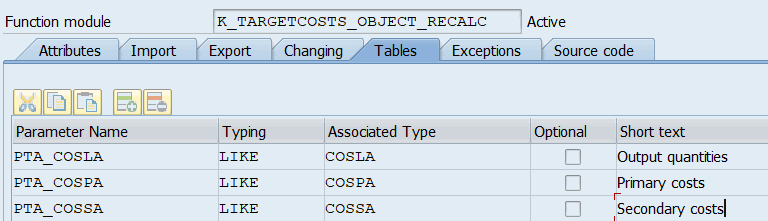

Due to various reasons ( export control, management reporting etc.), we have to provide the break-up of the cost into various categories or a specific cost category. Function module K_TARGETCOSTS_OBJECT_RECALC will provide cost break up & populate data into 3 internal tables with costs split into primary and secondary costs. Using these 3 internal tables you can find any component/category of product costing in SAP.

Demo implementation:

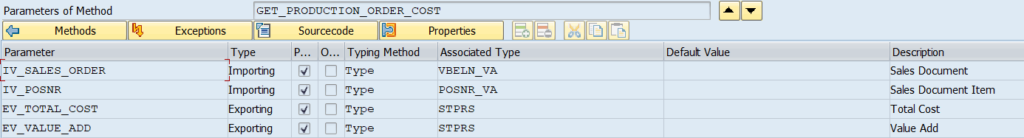

My requirement was to find total cost ( primary + secondary ) and value Add ( secondary costs only ). I created a method with Sales order and item number as input & costs ( total & value add ) as output. Your calculation requirement may vary so you can adjust the calculation part as per your conditions:

METHOD get_production_order_cost.

TYPES: BEGIN OF ts_afpo,

aufnr TYPE aufnr,

meins TYPE meins,

psmng TYPE lstxx,

END OF ts_afpo.

TYPES: BEGIN OF ts_aufk,

bukrs TYPE bukrs,

kokrs TYPE kokrs,

objnr TYPE cosla-objnr,

END OF ts_aufk.

*-- Local data declaration

DATA: lt_cosla TYPE TABLE OF cosla,

lt_cospa TYPE TABLE OF cospa,

lt_cossa TYPE TABLE OF cossa,

ls_afpo TYPE ts_afpo,

ls_aufk TYPE ts_aufk,

ls_cospa TYPE cospa,

ls_cossa TYPE cossa,

lv_gstrs TYPE sy-datum,

lv_gjahr TYPE gjahr,

lv_buper TYPE monat,

lv_field TYPE char10,

lv_cost TYPE stprs,

lv_poper TYPE t009b-poper.

FIELD-SYMBOLS <fs_cost> TYPE any.

*-- Clear variables

CLEAR:lt_cosla,

lt_cospa,

lt_cossa,

ls_cospa,

ls_cossa,

ls_afpo,

ls_aufk,

lv_gstrs,

lv_gjahr,

lv_buper,

lv_field,

lv_cost,

lv_poper.

*-- Get Production Order data based on selection parameters.

SELECT SINGLE aufnr

meins

psmng

FROM afpo

INTO ls_afpo

WHERE kdauf = iv_sales_order

AND kdpos = iv_posnr.

IF sy-subrc = 0.

SELECT SINGLE bukrs kokrs objnr

FROM aufk

INTO ls_aufk

WHERE aufnr = ls_afpo-aufnr.

IF sy-subrc = 0.

SELECT SINGLE gstrs

FROM afko

INTO lv_gstrs

WHERE aufnr = ls_afpo-aufnr.

IF sy-subrc = 0.

*-- Get fiscal year & period

CALL FUNCTION 'BAPI_COMPANYCODE_GET_PERIOD'

EXPORTING

companycodeid = ls_aufk-bukrs

posting_date = lv_gstrs

IMPORTING

fiscal_year = lv_gjahr

fiscal_period = lv_buper.

IF lv_gjahr IS NOT INITIAL AND lv_buper IS NOT INITIAL.

lv_poper = lv_buper.

*-- Get production order costs

CALL FUNCTION 'K_TARGETCOSTS_OBJECT_RECALC'

EXPORTING

par_awvrs = '000'

par_gjahr1 = lv_gjahr

par_gjahr2 = lv_gjahr

par_kokrs = ls_aufk-kokrs

par_meinh = ls_afpo-meins

par_menge = ls_afpo-psmng

par_objnr = ls_aufk-objnr

par_poper1 = lv_poper

par_poper2 = lv_poper

TABLES

pta_cosla = lt_cosla

pta_cospa = lt_cospa

pta_cossa = lt_cossa

EXCEPTIONS

targetcosts_impossible = 1

version_invalid = 2

system_error = 3

OTHERS = 4.

IF sy-subrc <> 0.

CLEAR: ev_total_cost,

ev_value_add.

ELSE.

*-- Cost Calculation

CONCATENATE 'WTG0' lv_buper INTO lv_field.

LOOP AT lt_cospa INTO ls_cospa.

ASSIGN COMPONENT lv_field OF STRUCTURE ls_cospa TO <fs_cost>.

IF <fs_cost> IS ASSIGNED.

lv_cost = <fs_cost>.

ev_total_cost = ev_total_cost + lv_cost.

CLEAR: lv_cost.

UNASSIGN: <fs_cost>.

ENDIF.

ENDLOOP.

LOOP AT lt_cossa INTO ls_cossa.

ASSIGN COMPONENT lv_field OF STRUCTURE ls_cossa TO <fs_cost>.

IF <fs_cost> IS ASSIGNED.

lv_cost = <fs_cost>.

ev_total_cost = ev_total_cost + lv_cost.

ev_value_add = ev_value_add + lv_cost.

CLEAR: lv_cost.

UNASSIGN: <fs_cost>.

ENDIF.

ENDLOOP.

IF ls_afpo-psmng IS NOT INITIAL.

ev_total_cost = ev_total_cost / ls_afpo-psmng.

ev_value_add = ev_value_add / ls_afpo-psmng.

ENDIF.

ENDIF.

ENDIF.

ENDIF.

ENDIF.

ENDIF.

ENDMETHOD.I hope you like this post on how to get costs breakup in production order for Make to Order scenario. You can write to us in case of any query/suggestion/feedback. Happy learning !